2023-03-07

Xinfangtai steel lattice plate is currently the world's most advanced, computer-controlled steel lattice plate high pressure resistance welding machine manufacturing, manipulator automatically cross bar (twisted rod or round rod, the same as the following) placed horizontally on the uniform array of flat steel, through the powerful welding power of 1600KVA and liquid pressure 1000KN cross bar pressure welding into flat steel, so as to get strong solder joints, High quality steel grid with high stability and strength.

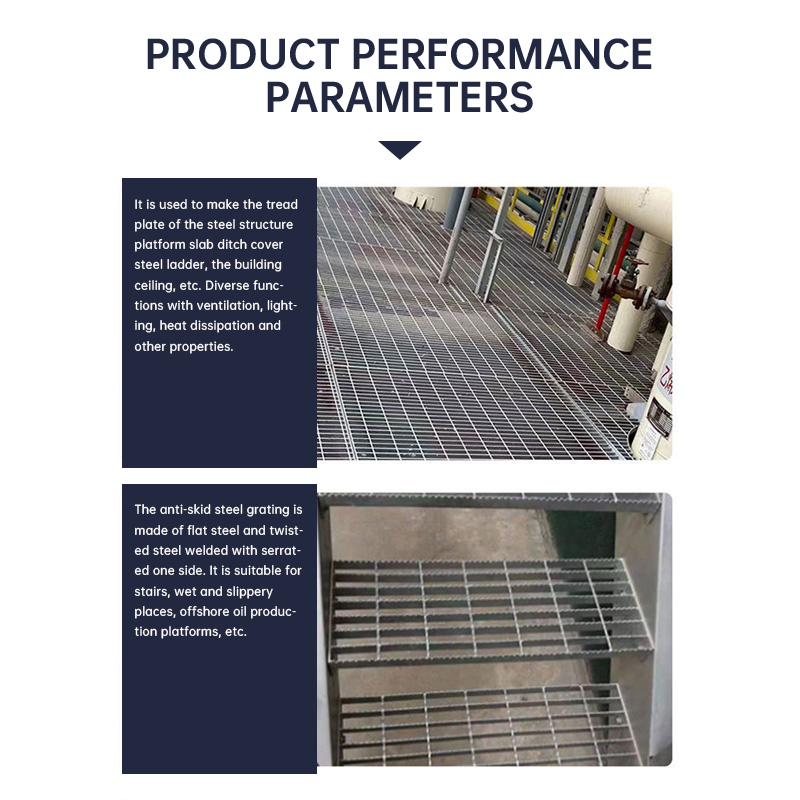

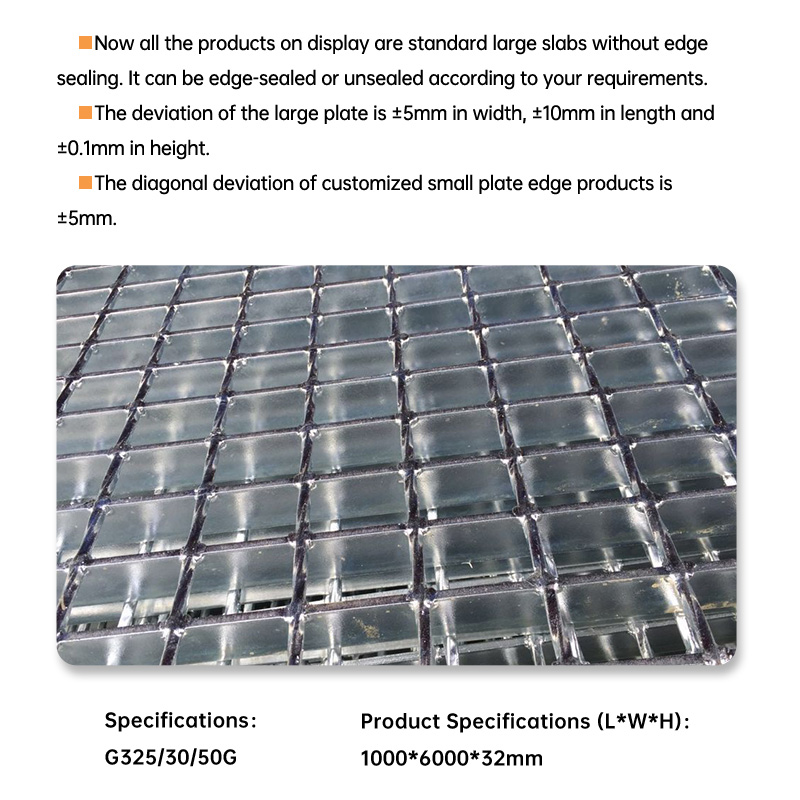

The hot-dip galvanized steel grating plate is made of 6000mm long bearing flat steel and 1000mm transverse bar, which are combined by pressure welding and fixed in a certain distance. The surface was treated with anticorrosion and rust prevention hot dip galvanizing process. All kinds of specifications and sizes can be customized according to actual needs. Widely used in power plant, chemical industry, sewage, airport oil depot, wharf gutter, electric power, scenic spots, paper, municipal, oil, light rail and so on.

Compared with pattern steel plate and other grilles, Xinfangtai steel grilles have the following advantages:

1, save materials: bear the same load conditions under the most save the way of materials, accordingly, can reduce the support structure of the material.

2, reduce investment: provincial material, provincial labor, provincial construction period, free from cleaning and maintenance.

3, the construction is simple: in the pre-installed support with a screw clamp, one person can complete.

4, save time: the product without on-site reprocessing, installation is very fast.

5, durable: before leaving the factory by hot zinc anticorrosion treatment, strong impact resistance and pressure.

6, modern style: beautiful appearance, standard design, ventilation and light, give a person with the overall smooth modern feeling.

7, light structure: less material, light structure, and easy to load and unload.

8, anti fouling: do not accumulate rain, snow and dust.

9, reduce wind resistance: because of good ventilation, small wind resistance in case of strong wind, reduce wind damage.

10, convenient design: no small support beam, simple structure, simple design; No need to design steel grid plate details, only indicate the model, the factory can design for customers.

11, ventilation, lighting, heat dissipation, explosion-proof, anti-skid performance is good.

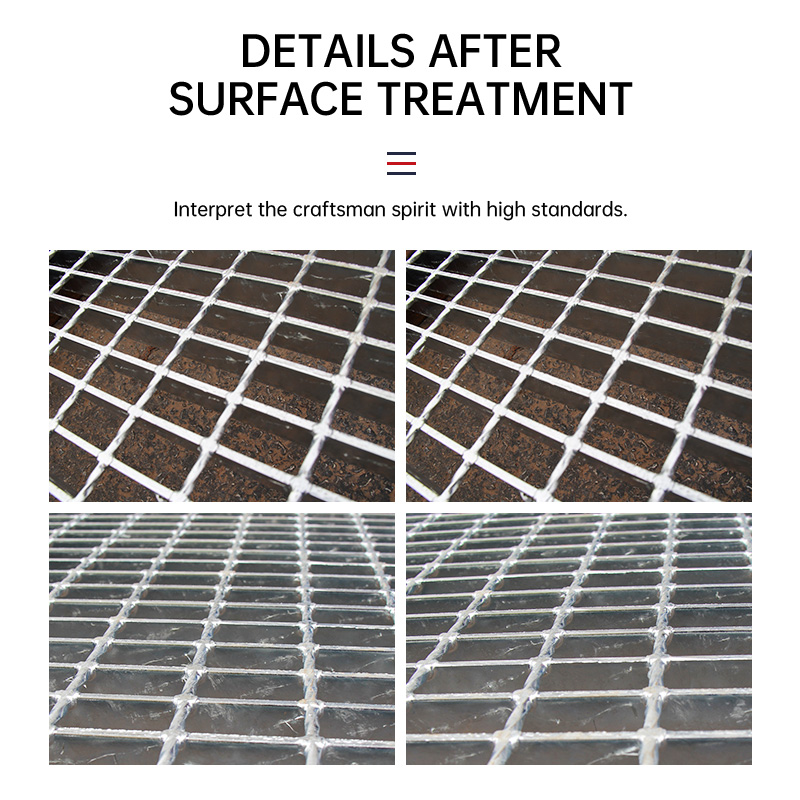

Chongqing Xinfangtai Metal Manufacturing Co., Ltd. is located in the world famous Internet red city, mountain city Chongqing, the geographical location of the economic center of the upper reaches of the Yangtze River in China, is also the source of the "Chongqing-Xinjiang-Europe" international railway combined transport channel - Chongqing, the factory was established in 2001, after continuous development, In combination with the market prospect, the company set up the first production base of pressed welded steel lattice plate in 2008, covering an area of about 8000 square meters, with 125 employees and 9 technicians. In 2021, the company also introduced the high-frequency intelligent steel lattice welding production line, which can weld the penetration of twisted rod with flat steel through high voltage current, and the steel lattice plate after welding is beautiful in appearance. After pressing welding, according to the customer's requirements, high-speed cutting machine is used for block cutting. After cutting, black semi-finished products are wrapped and welded on both sides. After welding, the steel grid is smooth and polished, and then waiting for hot-dip galvanizing treatment or surface treatment according to the customer's requirements.

Intelligent pressure welding production line to improve the production capacity and production quality, in the management has already passed the ISO certification system, constantly strengthen and improve, the leading products are the platform of hot-dip galvanized steel grid, all kinds of ditch cover, stair pedals, handrails, small steel structure. The production of hot-dip galvanized steel grid is beautiful in appearance, design specifications, impact and weight resistance, open use without rain, snow and dust; With provincial materials, provincial construction period, provincial labor, installation is also very convenient; Can ventilation, lighting, heat dissipation explosion-proof, anti-skid performance is good; After hot dip galvanizing, corrosion resistance and other characteristics, has been recognized by the majority of customers. Its ventilation and light transmission performance, chemical design institute all recommend the use of steel grid plate instead of the previous pattern plate; Impact and pressure resistance is widely recommended by shipping design institute, transportation design institute for logistics yard, port terminal, airport, light rail, chemical industry, scenic spots, sewage plants, wineries, thermal power plants, electrolytic aluminum plants; Its versatile performance, but also recommended by the electric power design Institute for the main factory floor. Because of the spirit of customer first, integrity first purpose, pay attention to each business, obtain a number of honor well won the trust and praise of our customers!

Sun Yaxi

156543894@qq.com

05-13

05-13

05-12

05-12

05-12

05-12

05-12

05-12

05-12

05-12